WEM6000 was developed with 70 years of global feed-mill experience and 100% focused on the three things that matter: uptime, quality, performance analytics.

Intuitive UI: faster information detection and reaction to nonstandard conditions. Customizable layout and color schemes.

Faster detection and recovery from unplanned stops: operators spend less time chasing problems, recover faster when something goes wrong, fewer small issues turning into long outages.

Ready for predictive maintenance readiness: fewer catastrophic failures and lower urgent repair costs.

Asset protection and risk reduction: significant downtime and asset replacement cost avoidance.

Consistent product quality, every run: fewer rejects, less rework, higher quality.

Stage Batching Orders: fewer manual interactions during production, data entry errors, and a more predictable and consistent production flow.

Dynamic Batch control: Ability to stop batch runs, run an ad hoc batch and resume original batch run.

Operator-first UI & reduced training burden: fewer operator errors, faster ramp for new hires.

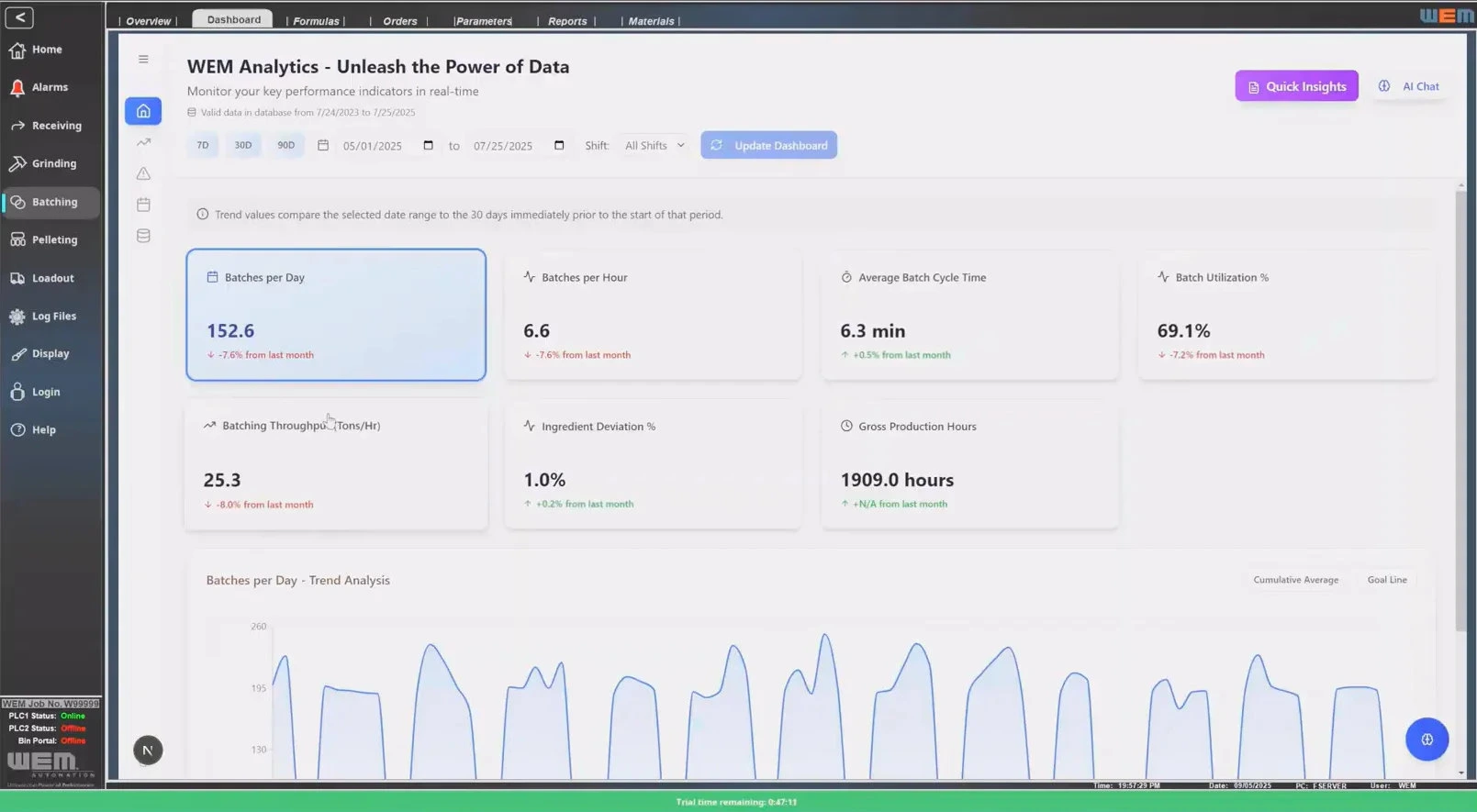

Actionable shift-level analytics: performance visibility and comparability between shifts, enabling objective review and accountability.

AI-Augmented Performance Analytics: Clear, actionable insights that enable better operational and production decisions.

Real, measurable throughput gains: sustained, on target, throughput through performance trends and losses visibility.

Traceability that saves: audits and recalls handled in minutes, not hours.